Asphalt Reinforcement

Asphalt Reinforcement

Existing Asphalt problems

- Temperature expandability between materials varies significantly depending on days, nights and seasons.

- The fatigue of the package is weighted by repeated and constant traffic overload.

- Asphalt concrete for road pavement construction materials is the most durable and economical material. However, the stress in the shear zone is extremely low in physical propertie

- Cracks in asphalt can reduce the stiffness of paved roads and allow water infiltration, leading to further deterioration of the foundation ground and surface layer.

-

Fatique and Reflective Cracks

-

Plastic deformation

-

Pothole

BMK Asphalt Reinforcement

-

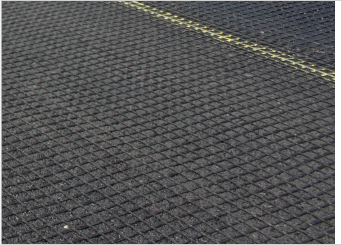

BMK-AE60 is composed of a Fiberglass Grid surface coated with Bitumen.

Additionally, BMK-AE60N, which is used on uneven cut surfaces, features a non-woven fabric attached to the backside. - Asphalt reinforcement material BMK-AE60 combines the compressive force of asphalt with the tensile strength of fiberglass to create an ideal structure.

- The combined reinforcement material serves as the structural framework for strengthening the asphalt layer and prevents cracking in the foundation grade by increasing the tensile strength of the asphalt layer.

- It exhibits excellent chemical resilience, thermal resilience, and outstanding crack prevention performance at low temperatures.

BMK-AE60

BMK-AE60 (60 / 60 kN/m)

this is a Fiberglass Grid surface coated with Bitumen.

BMK-AE60N

BMK-AE60N (60 / 60 kN/m)

It is in the form where non-woven fabric is attached to the grid, protecting the grid on cut surfaces or uneven surfaces.

Geosynthetic reinforced specimens have been found to be 5 to 10 times more effective in crack suppression than unreinforced specimens and glass fiber grids are about 2 times more resistant to cracking than polyester grids. It is considered that this is affected by the elongation of the grid.

Fiber reinforcements can be installed between asphalt layers to stop or retard cracks already occurred in the lower layers.

Geosynthetic fiber attached to the lower surface of the asphalt surface disperses the load and suppresses the crack propagation due to the low thermal strain and high tensile strength of the glass fiber.

A Study on the Crack Resistance Characteristics of Geogrid Reinforced Asphalt Pavement (Hyangyang University Lee, Hyun-ho. Dec 2015)

Evaluation of early commonness of fiber grid reinforced asphalt pavement (Collection of dissertations of Korean Society of Road Engineers, Vol. 12, No. 4)

Crack Improvement Effect of Asphalt Pavement Reinforced by Glass Fiber Sheet

Asphalt Reinforcement Certification

-

-

Application of Quality Test Report

-

Test Result Report

-

Test Result Report

2021 Road Pavement Management System

Final Report / Ministry of Land, Infrastructure and Transport, March 2022 (Research Institution: Korea Institute of Construction Technology)

6.4.6 Introduction and Application of Special Paving Methods

As of December 2020, the total length of roads in South Korea stands at approximately 112,977 kilometers, thanks to continuous investments, including new construction and expansion projects. Among these roads, around 98,683 kilometers (87.3%) have been paved.

Asphalt paving, which constitutes a significant portion of South Korea’s paved roads, has faced a major issue due to frequent occurrences of rutting, caused by factors such as increased heavy vehicle traffic and high temperatures during the summer season, leading to a rutted road. This has become a significant concern for the country’s road infrastructure.

Starting from 2008, a test installation of the fiber grid method, which involves attaching fiber-reinforced material made of glass and carbon fibers to the road surface and then applying the surface layer, has been conducted. This method aims to prevent structural damage to road pavements in advance, promoting comfortable road travel and budget savings. In this project, we classified construction methods based on the characteristics of the special pavement methods and applied them differently depending on the site conditions.

Grid + 5AC Method

The Grid + 5AC method is applied to enhance the durability and extend the lifespan of pavement that has experienced significant rutting or cracking. It is primarily applied in areas with a high volume of heavy vehicle traffic, and the following criteria can be used to determine its application.

It involves the installation of high-elasticity carbon and glass fiber woven reinforcement materials beneath the asphalt overlay. These reinforcement materials help supplement the inadequate tensile strength of the asphalt pavement, thereby suppressing rutting, preventing , and reducing reflection cracking.

The Grid + 5AC method has been implemented in test pavements since 2008, and continuous monitoring and follow-up studies have been conducted.

- Maintenance and reinforcement of existing roads (overlaying of sections prone to reflection cracking).

- Asphalt pavement sections suspected of damage due to structural issues or those with a high degree of cracking

- New roads (routes with heavy traffic, intersections, and uphill road lanes)

- Industrial roads, connections to industrial complex, and airport taxiways, etc.